Agile solution to communication challenges at a heating plant

Versowood, a company based in Vierumäki, has deployed the PlantSys suite of tools. Versowood’s heating plant supplies the company’s production process and a small number of district heating customers. The plant focuses on renewable and cost-effective Finnish energy sources. Versowood’s heating plant uses three components of the PlantSys suite: Operation, Reporting and Diary.

“Without a doubt, the biggest challenge that PlantSys has resolved for us is reducing the amount communication on paper, thereby eliminating the chance of human error. Everyone working a shift can open the Diary app to see all the relevant information and any adjustments made during the previous shift,” says Arttu Särkkä, Operation Manager at the heating plant. Särkkä has worked in heating and power plants since the early 2000s.

Versowood uses the Diary app for operational communication and other purposes. The Diary makes it easy to handle all other communication with personnel, such as reminders and announcements. A common view makes the same information available to everyone. Information about repair needs, plant tours and plant equipment is also shown in the same place.

“Many practical problems in plants like ours are caused by a lack of internal communication. People do not know what has been planned and whether the boilers were adjusted during the previous shift. It is important for staff on shift to know about planned shutdowns, maintenance procedures, and similar measures.”

Different facilities on one screen

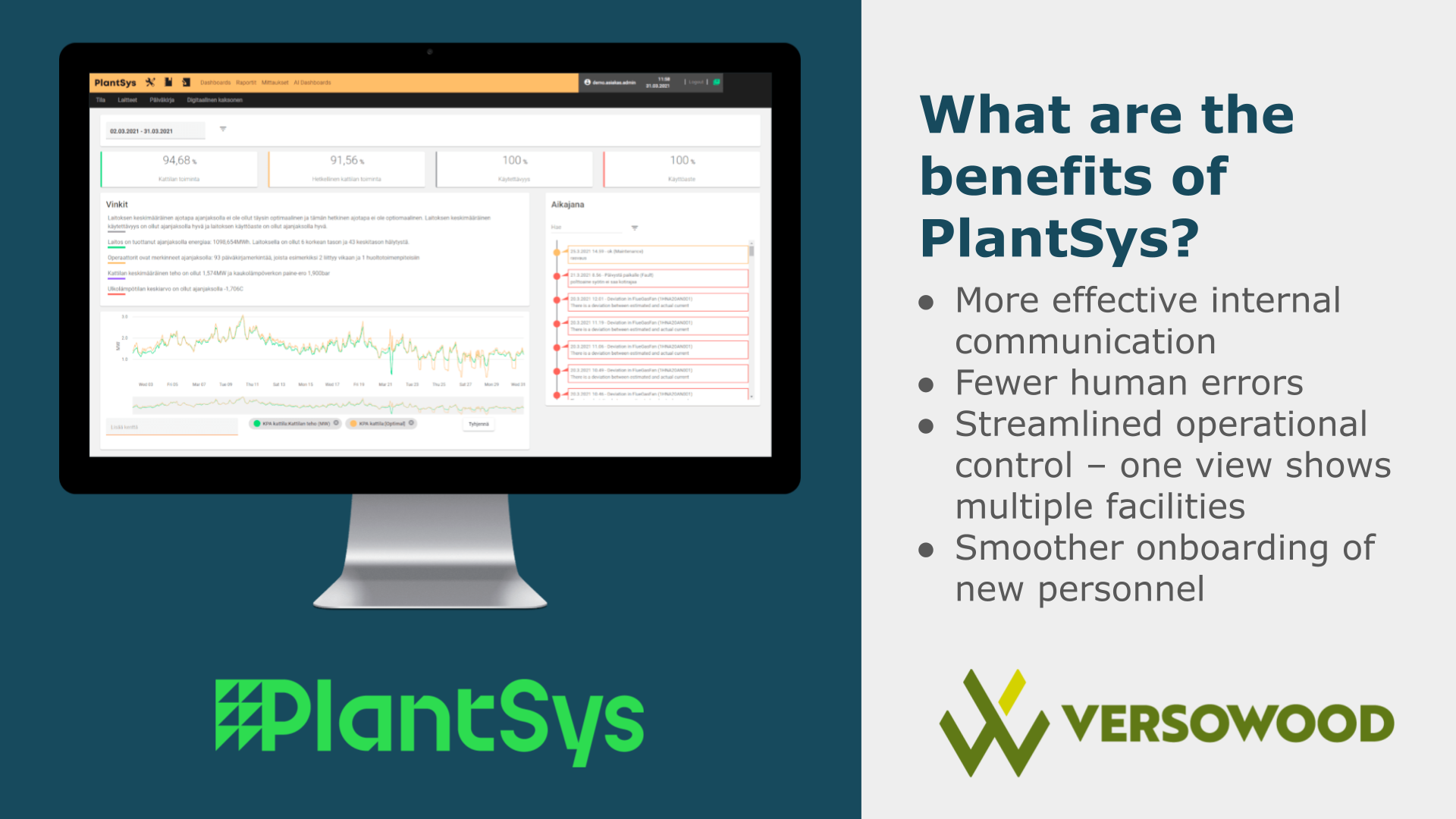

PlantSys Operation brings different facilities into a single view, allowing for convenient and comprehensive monitoring and control of the operation of several different heating plants and individual boilers in the area.

“Our people like having everything shown clearly in one view. It makes the job easier and clearer,” says Särkkä.

Thanks to the clear, visually appealing view, it is relatively easy for new employees to get to grips with plant operations. A single view shows a wide range of processes, with more detailed information about various components just a click away.

“Of all the PlantSys tools, Reporting is a great help for me as the operation manager, as I am responsible for the plant’s operation,” says Särkkä.

“In the past, we needed to go and read all the gauges and look through the notes on each site, which was a laborious, time-consuming process. Now, PlantSys Reporting puts all the same data right in front of me without requiring separate site visits. The Reporting tool provides valid, complete and reliable information.”

Versowood also appreciates the PlantSys customer support:

“Product support works really well – you get answers without delay. The service is good, and things are taken care of quickly. Everything is usually sorted out at the first time of asking.”