Artificial intelligence and Machine learning

PlantSys Real-time condition monitoring

Predictive maintenance, uninterrupted production

Equipment failures and unexpected production outages can cause significant costs and disruption to production. Real-time condition and industrial AI solutions enable the identification of failures before they escalate.

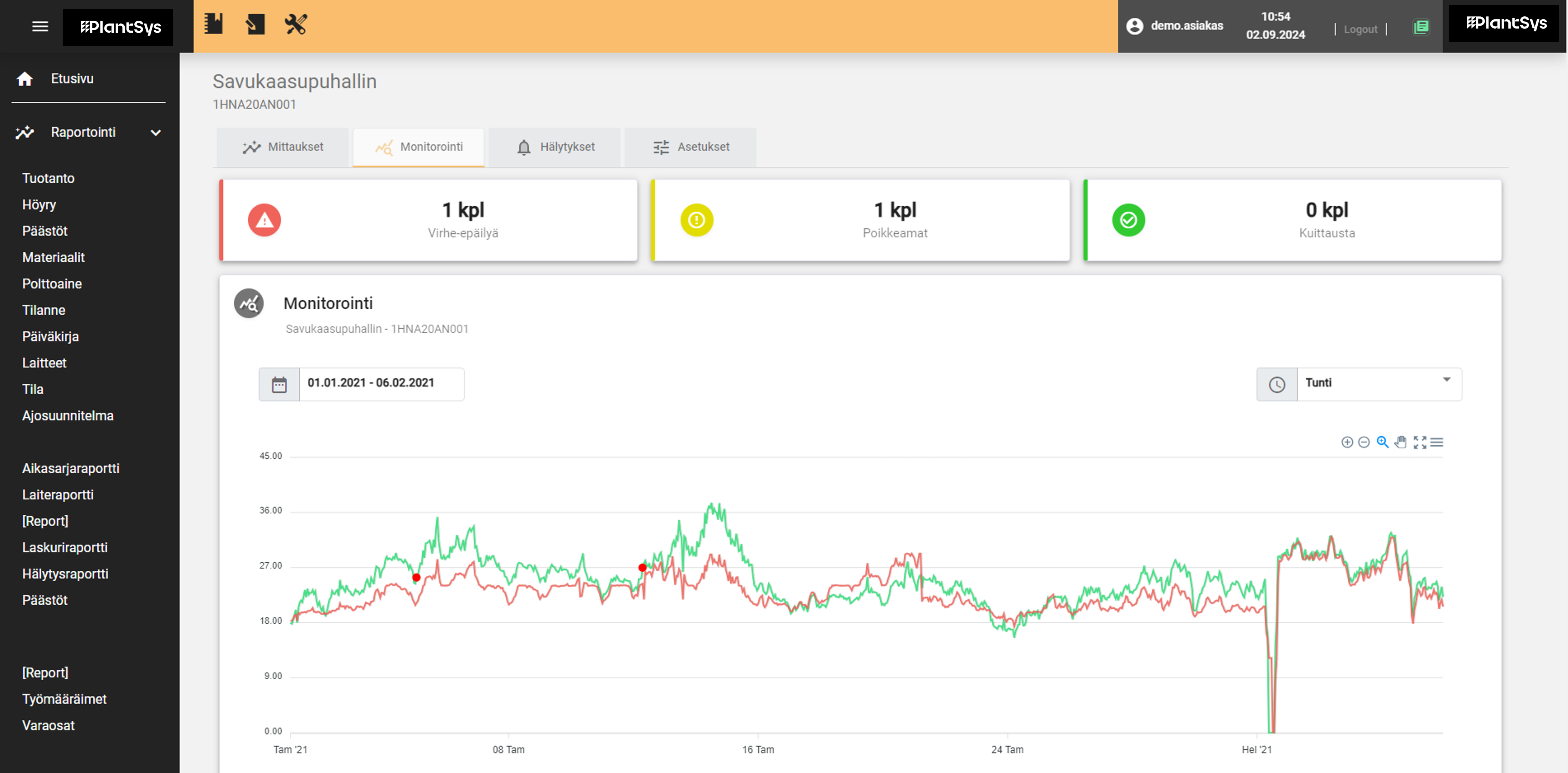

PlantSys Real-Time Condition Monitoring uses AI and real-time data to ensure that equipment is operating optimally and maintenance is carried out at the right time. The system monitors equipment performance, identifies anomalies and predicts maintenance needs, minimising downtime and extending equipment life.

Benefits for our customers

- Less production downtime – detects faults early and prevents costly downtime.

- Optimal maintenance – maintenance is only carried out when it is needed.

- Significant cost savings – reducing unnecessary emergency repairs and downtime.

Interested?

Please leave a request for a quote using the link below, and we can talk more about the real-time condition monitoring.

Key features

Predictive maintenance and fault diagnosis

- AI-based predictive maintenance – identifies incipient problems and optimises service timing.

- Real-time monitoring and alerts – continuous monitoring and automatic notifications.

- Intelligent reporting and analytics – clear KPI metrics and visual reports on equipment condition.

- Cost-effective maintenance planning – timely maintenance, fewer unnecessary repairs.

PlantSys Real-Time Condition Monitoring ensures that your production runs without surprises – more efficiently, safely and profitably.