Reactive maintenance causes unexpected downtime, scheduled maintenance ties up resources, and overly frequent maintenance practices add unnecessary costs.

Does maintenance control you, or do you control maintenance?

The PlantSys Real-time condition monitoring system completely changes this dynamic. It not only prevents problems, it predicts them before they happen. This makes maintenance a strategic competitive advantage – not just a necessary expense.

What is Real-time condition monitoring system?

Real-time condition monitoring is the technology that will bring maintenance into the 2020s. The service uses data collected from the process of the equipment, which can be enriched with additional sensors if required. The data collected by these devices is analysed in real time by AI, and the system identifies even the smallest anomalies that could indicate an incipient failure.

This approach differs significantly from traditional maintenance models:

- In a reactive model, problems are fixed only when they occur, causing downtime.

- In the planned model, maintenance is carried out according to a calendar, often without any real need.

- In the proactive model, which PlantSys enables, maintenance is only carried out when it is genuinely needed and before problems affect production.

How PlantSys works

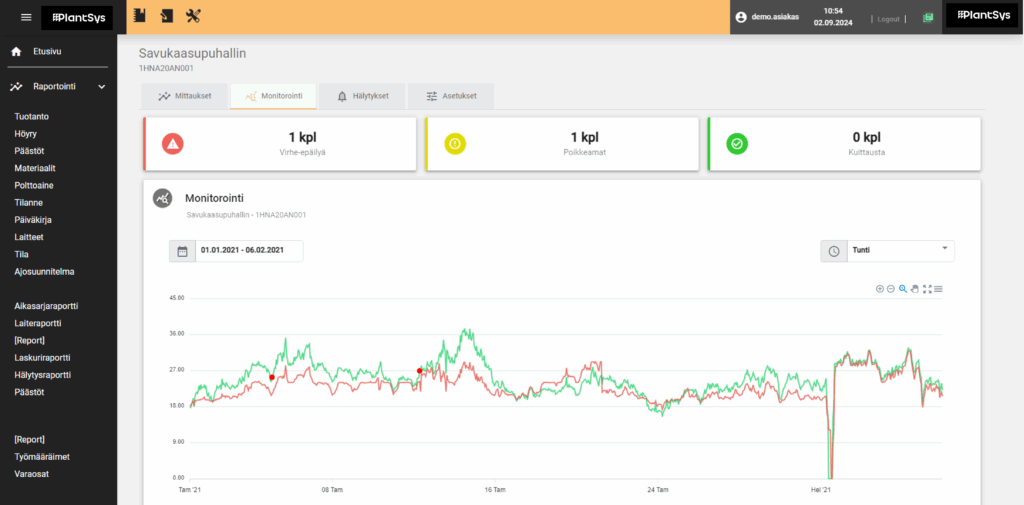

PlantSys has been developed for complex and demanding industrial environments. The system is designed to provide real-time visibility, automated analytics and seamless integration.

This is how PlantSys brings concrete benefits to your production:

- Real-time monitoring: The system continuously monitors the data sent by each device, such as the sweeping speed and electricity consumption. Additional sensors can be used to measure vibration and temperature, for example. The data is analysed in real time, providing users with an easy-to-understand view of the status of the system or equipment.

- Anomaly detection: the PlantSys AI identifies trends and anomalies that traditional systems would miss. This allows early detection of incipient problems.

- Predictive maintenance: AI not only analyses data in the present, but also predicts future events. It suggests timely actions, such as ordering spare parts, adjusting equipment or scheduled maintenance.

- Integration and scalability: PlantSys can be integrated into existing systems such as ERP and control room solutions. The system scales to any size of plant, from a single production line to a group-wide system.

Change starts today

Would you like to make maintenance a competitive advantage? Contact us and let’s see how PlantSys can serve your production.

Read more about PlantSys Real-time condition monitoring system