Unlocking hidden potential

An SMB in manufacturing, energy production or production industry in general often do not have the knowledge on how to utilize the data gathered from production processes. Some more digitally savvy leaders recognize the possibilities on how to potentially optimize their production lines with, especially in the AI-era. They however might not have the resources, have skill gaps or are missing exact direction on where to start the journey.

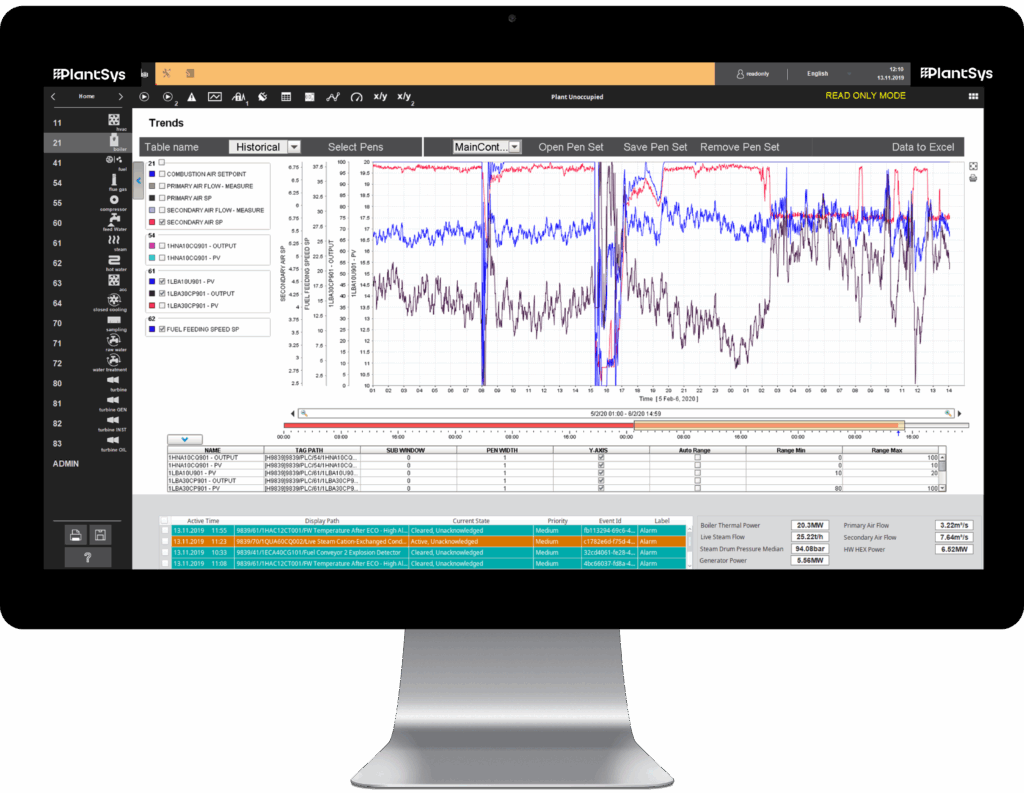

At PlantSys, we understand that data holds immense potential. However, we also see the challenges that businesses face when trying to use it effectively. That’s why we’re thrilled to develop PlantSys. Empowering our customers to harness their data effectively and steer their business in the best direction, all without the hassle of initiating a large, complex internal IT project.

Make existing data visible

Many company functions operate unbeknownst of what other parts of company is doing and how the similar existing processes could be shared. It’s not that companies deliberately end up in such situations, it’s rather accidental and happens then it’s not actively being taken care of.

Industry plant maintenance is a good example of such situations. This is where PlantSys Maintenance module helps companies to expose their data internally to different functions of the company. PlantSys Maintenance module enhances collaboration by making different maintenance cycles, device and equipment locations, spare part counts and locations are made clearly visible in many parts of the organization. Traditionally that information must be deliberately asked by various teams or people slowing down the collaboration. Curious to hear more? Get in touch with Olli.

Prepare yourself for the AI era

We at PlantSys are excited about the potential of AI in improving processes and understanding of the business in general. Industrial processes are often complicated, involving many machines, equipment, and physical principles. In the past, it took a lot of resources and effort to calculate live optimizations for these processes. This is because they involve many data points from different sensors, complex formulas, and a large amount of data over time that needs to be analyzed to ensure accurate optimization.

This is where AI really shines, it can analyze vast number of data points from long periods of time and based on that it can come up with optimizations very quickly. We see that this makes it possible to optimize different kinds of industrial processes, be it heat production, manufacturing, and practically any automation-controlled production. We’re closely keeping our eye on the matter and doing our own R&D with pilot customers around this topic.

What makes all this possible is simply data, data and data. Both the quantity and quality of it, meaning that sooner you start collecting quality data better positioned you are for harnessing the AI capabilities now or in the future.

Would you like to talk more about your needs and ideas in this area?